Hydraulic Ferrule Fittings by Gem Engineering

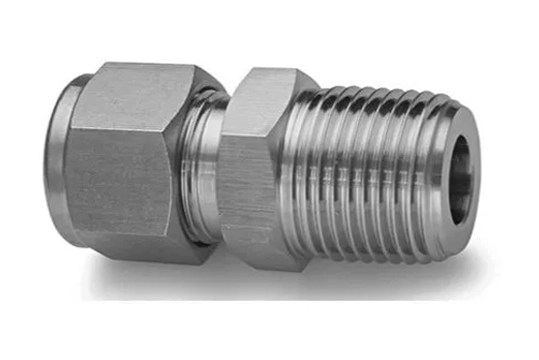

Hydraulic ferrule fittings are a specific type of compression fitting commonly used to connect hydraulic hoses to various components within hydraulic systems.

Gem Engineering, a leading manufacturer of hydraulic fittings, offers high-quality hydraulic ferrule fittings for your fluid power needs. These fittings ensure reliable, leak-proof connections in hydraulic systems that transfer pressurized fluids.Here are the key aspects and features of hydraulic ferrule fittings.

Design and Construction

A hydraulic ferrule fitting consists of a metal sleeve (ferrule) that is placed over the end of a hydraulic hose.

The ferrule is typically made from materials such as steel or stainless steel, chosen for their strength and durability under high pressure and in harsh operating conditions.

Sealing Mechanism

The ferrule fitting utilizes compression to create a tight seal between the hydraulic hose and the fitting body.

Inside the ferrule, there is often a separate sealing ring or seat (typically made of elastomeric material like rubber or synthetic polymers) that helps to create a leak-proof connection when compressed against the hose and fitting.

Assembly Process

To assemble a hydraulic ferrule fitting, the hydraulic hose is inserted into the fitting body until it reaches a stop.

The ferrule is then slid over the hose end and positioned between the hose and the fitting body.

Using a crimping tool, hydraulic pressure is applied to compress the ferrule around the hose and against the fitting body, thereby securing the hose in place and creating a reliable seal.

Advantages

Reliable and leak-free connection: The compression and sealing mechanisms of ferrule fittings ensure that hydraulic fluid does not leak under pressure.

High-pressure capability: Ferrule fittings are designed to withstand high hydraulic pressures commonly encountered in hydraulic systems.

Durability: Materials used (such as steel or stainless steel) provide strength and resistance to corrosion and wear, ensuring long-term reliability.

Applications

Ferrule fittings are used in a wide range of hydraulic applications across industries such as construction, agriculture, manufacturing, and transportation.

They are commonly found in hydraulic systems for machinery like excavators, loaders, cranes, and agricultural equipment where reliable fluid transfer is critical.

Considerations

Proper selection of ferrule fittings involves consideration of factors such as hose size, operating pressure, fluid compatibility, and environmental conditions.

Regular inspection and maintenance of ferrule fittings are important to ensure they remain securely attached and leak-free over time.

In summary, hydraulic ferrule fittings are essential components in hydraulic systems, providing secure and leak-proof connections between hoses and other hydraulic components. Their robust design and reliable performance make them a preferred choice in demanding industrial applications.