Secure Connections with Gem Engineering Industries' Male Stud Coupling Sockets

When it comes to building robust and reliable fluid transfer systems, especially in demanding industrial applications, every component plays a crucial role. One essential element is the Male Stud Coupling Socket, a seemingly simple part that offers a secure and leak-proof connection. Here at Gem Engineering Industries, we understand the importance of quality, and our Male Stud Coupling Sockets are built to meet the most rigorous standards.

Understanding the Male Stud Coupling Socket

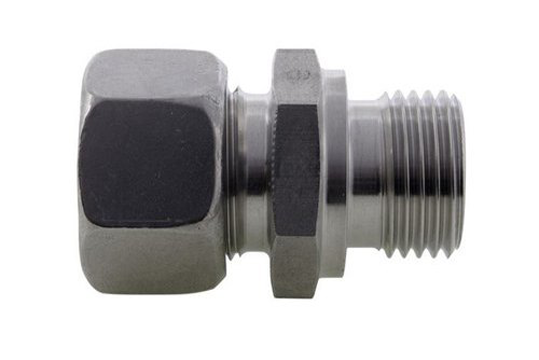

A Male Stud Coupling Socket, also sometimes referred to as a Straight Female Stud Coupling, is a fitting used to connect two pipes or tubes. It consists of a female body with internal threads on one end and a male stud on the other. The male stud features external threads that match the internal threads of the pipes or tubes being connected.

The female body of the Male Stud Coupling Socket from Gem Engineering Industries is designed to accept a variety of sealing mechanisms, depending on the application. These can include:

- O-rings: A versatile and cost-effective option, O-rings provide a reliable seal against leaks in many low to medium-pressure applications.

- ED Seal: An elastomeric lip seal designed for high-pressure applications, the ED seal offers exceptional performance and durability.

- Other seal types: Depending on the specific requirements of your project, Gem Engineering Industries can provide Male Stud Coupling Sockets compatible with various sealing solutions.

Benefits of Using Male Stud Coupling Sockets from Gem Engineering Industries

There are several advantages to incorporating Male Stud Coupling Sockets from Gem Engineering Industries into your fluid transfer system:

- Versatility: Our Male Stud Coupling Sockets are available in a wide range of sizes and thread types, ensuring compatibility with most commonly used pipes and tubes.

- Leak-proof connections: The combination of precision machining, high-quality materials, and effective sealing mechanisms guarantees a secure and reliable connection, minimizing the risk of leaks and system downtime.

- Ease of installation: The straightforward design of Male Stud Coupling Sockets allows for quick and efficient installation, even in confined spaces.

- Durability: Manufactured from robust materials like steel or stainless steel, our Male Stud Coupling Sockets are built to withstand the demands of harsh industrial environments.

- Corrosion resistance: Many of our Male Stud Coupling Sockets are available in corrosion-resistant materials, making them ideal for use with fluids that can cause degradation.

Applications for Male Stud Coupling Sockets

Male Stud Coupling Sockets from Gem Engineering Industries find application in a broad spectrum of industries, including:

- Oil and Gas: These fittings are essential for transferring fluids in various oil and gas exploration and production processes.

- Chemical Processing: The ability to handle harsh chemicals and withstand high pressures makes Male Stud Coupling Sockets suitable for chemical plants.

- Power Generation: Our Male Stud Coupling Sockets play a vital role in fluid transfer systems within power plants.

- Manufacturing: These versatile fittings are used in diverse manufacturing applications for conveying fluids.

- Construction: Male Stud Coupling Sockets can be employed in hydraulic and pneumatic systems used in construction equipment.

Selecting the Right Male Stud Coupling Socket for Your Needs

With a vast selection of Male Stud Coupling Sockets available, choosing the most appropriate option for your project requires careful consideration of several factors:

- Size: The size of the Male Stud Coupling Socket needs to match the outer diameter of the pipes or tubes you intend to connect.

- Thread type: Ensure the thread type on the male stud aligns with the threads on your pipes or tubes. Common thread types include BSPP, BSPT, NPT, and Metric.

- Material: The material selection depends on the type of fluid being conveyed, pressure requirements, and the operating environment.

- Sealing mechanism: Choose the sealing mechanism that best suits the pressure rating, fluid compatibility, and temperature range of your system.

Why Choose Gem Engineering Industries for Your Male Stud Coupling Sockets?

At Gem Engineering Industries, we take pride in offering superior-quality Male Stud Coupling Sockets designed to deliver exceptional performance and reliability. Here's what sets us apart:

- Unwavering commitment to quality: We utilize top-grade materials and stringent manufacturing processes to ensure every Male Stud Coupling Socket meets the highest standards.

- Diverse product range: Our extensive inventory caters to a wide array of applications with a variety of sizes, thread types, materials, and sealing options.

- Expertise and experience: Our team possesses in-depth knowledge of fluid transfer systems and can assist you in selecting the most suitable Male Stud Coupling Sockets for your specific needs.

- Customer focus: We prioritize customer satisfaction and provide exceptional service to ensure a smooth and successful experience.

For dependable and leak-proof connections in your fluid transfer system, look no further than Gem Engineering Industries'